I have long been a proponent of finding time throughout the day for the mind to be unoccupied. This serves as a preventive measure against entertainment addiction, and allows the mind to wander and come up with some of its best thoughts. While eating dinner a little while back, I had a thought that piqued the interest of my mechanical engineering-trained mind: what actually happens to foods as we chew them that causes them to break down? More technically, what is the failure mode, or modes, of foods when we eat them? Following that meal, I began paying more attention to my chewing than I’m sure most people ever will, in an attempt to find my answer. I came up with the following five modes of failure, which turned out to be a pretty good crash course on solid mechanics – the study of how solids react to loading.

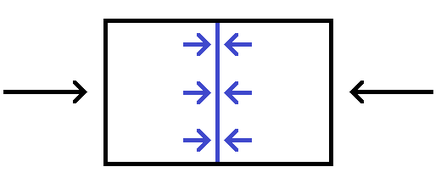

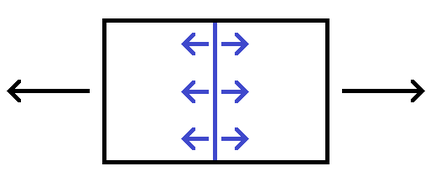

Before going into the failure modes, I’ll briefly explain the concept of stress (the engineering kind). Stress is the measure of force per unit area, and can be divided into two types: normal and shear. Normal stress is when the force is perpendicular to the plane you’re calculating the stress on, and shear is when the force is along the plane. Further, there are two types of normal stress – tension and compression, which differ in the direction of the forces. Normal (blue) and shear (red) stress are shown below

Compressive Normal Stress

Tensile Normal Stress

Shear Stress

As you can see in the diagrams, normal stress tries to pull the object apart or push it together, and shear tries to slide the piece past itself. Every material has a limit to the amount of stress it can see before it breaks, which is how engineers make sure parts won’t fail. The stress limits can differ between shear, compression, and tension, and even differ depending on direction. For example, wood is stronger when pulled along the grain than against it.

Most real life objects under stress have very complex combinations of the different types of stresses that vary with location on the part, but I will try to keep it as simple as possible in my description of the failure modes of foods.

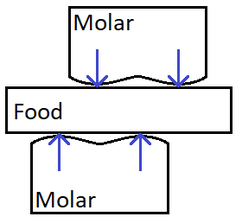

Mode 1 – Molar Shear and Compression

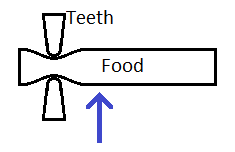

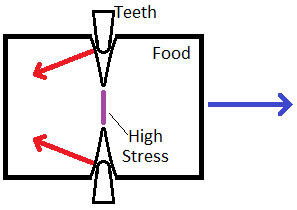

I chose this as the first failure mode because it is the most commonly used – it is the method used to break down foods to a swallow-able size. This is done by clamping down on the food repeatedly with your molars. The molars are wide, ridged, and offset from one another, which makes them good for applying compressive and shear loads.

The blue arrows show the location and direction of forces applied by the molars. Because the forces are offset from each other, they create shear stress on the vertical planes between the force application points. This can either cause the food to break along those planes, or deform. Either way, the molars will also create compressive stress that can cause the food to break. Each bite thus breaks the food into smaller pieces until it’s fine enough to swallow.

Mode 2 – Tension

This is the simplest method from a mechanical standpoint. A prime example is biting off part of piece of beef jerky. It is done by clamping one end of the piece between your teeth, and pulling the other end away from your teeth. This puts the part between your teeth and hand in tension, which will eventually cause it to fail once the applied force is large enough.

Beef jerky is an example of something that has very different stress limits depending on the direction the stress is in. If it’s pulled in the direction of its grain, it will be difficult to break off a piece, but if it’s pulled against the grain, it will break easily. In the first case, the person eating it will often look to shear as their next option to more easily bite off a piece. That is the next mode.

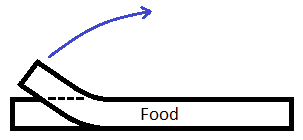

Mode 3 – Shear Stress Crack Propagation

This mode mimics the way people typically rip paper. We’ll continue with the jerky example here. To do this, you clamp the piece in your teeth just as in Mode 2, but instead of pulling away from your teeth, you pull the piece up to apply a shear stress to the jerky.

The key here is to grab the piece close to your teeth and start on one of the end of the piece to concentrate the applied load in a small area, creating high stress in that area. This same process is naturally followed when ripping a piece of paper. Once the end fails in shear, a crack begins, and by using a similar motion to pealing tape off a surface, you can extend this crack until it reaches the other end and completely breaks the piece in two. The image below depicts this. Note that, while the teeth aren’t shown in this image, the perspective here is looking at the teeth, not along the teeth, as in the previous image. The perspective has rotated 90 degrees.

Mode 4 – Normal Stress Crack Propagation

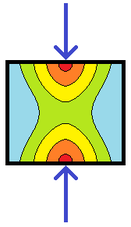

This mode is best exemplified by taking a large bite out of an apple. There are two steps to this process. The first is starting the crack at the surface of the apple, which is done by applying a point force with your front teeth. This creates a small area of high compressive stress, which fails, allowing your teeth to sink into it. The image to the right shows this, with the colors indicating the stress levels created by the forces: red is the highest stress, blue is the lowest.

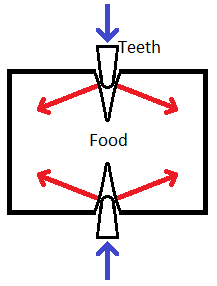

Once the crack is formed and your teeth are inside it, the crack is then propagated by using your teeth as a wedge. A wedge is one of the six simple machines. It is able to magnify the force input to it, with the output force being at a different angle. In the image below, the blue arrows are the forces the jaw applies to the teeth, and the red arrows are the forces the teeth apply to the food. The lengths of these arrows are proportional to the magnitude of the force they represent.

As you can see, the teeth exert a force that pushes the two sides of the crack apart, which creates high tensile stress in the area where the crack ends. This makes that area fail, which makes the crack grow longer. This process continues until one of the following happens: (1) the cracks your top and bottom teeth are forming meet, and the piece is fully bitten off, or (2) the area remaining uncut by your teeth is small enough that you can break it off in tension by pulling the apple away from your teeth (shown below).

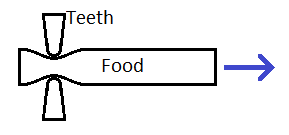

Mode 5 – Three Point Bending

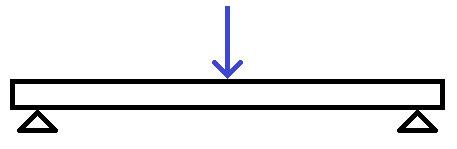

The final mode (or at least the last one I can think of) mirrors a destructive testing method used to find the properties of materials. It’s called three point bending, because it involves applying three point forces on an object – typically long and thin – in order to bend it.

The supports shown on either end in the image both apply an upward force to counteract the downward force applied. The two outer forces are always in the same direction, and the inner is in the opposite direction. This is an effective way to bite a piece off of a relatively long and thin food that is rigid. Examples include long carrots and chocolate bars. The three point bending is created by moving your jaw forward so your bottom front teeth extend past your top front teeth, then biting the food in that way, and pulling the other end down with your hand. When this is done, your bottom teeth exert an upward force, and your top teeth and hand both exert a downward force.

In three point bending of a beam with a uniform cross section, the highest stress always occurs at the point where the middle force is applied, no matter where that is along the beam. This means that, unless the cross section or the failure stress varies along the food item, the piece will break at your bottom teeth. This generally holds up in practice, in my own experience.

Beauty of the Mouth Layout

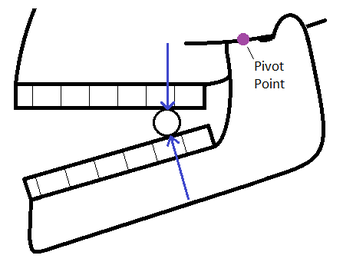

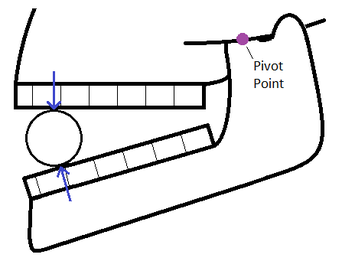

In looking into the different failure modes of food, I gained an appreciation for how well laid-out the mouth is. I described the front teeth as wedges – one of the simple machines – earlier in this piece, and the jaw can also be described as a simple machine: the lever. Levers are objects the rotate about a single point, which can be used to amplify forces. To give a technical explanation of this, I would need to define multiple terms and physical laws, so I’ll just leave it at this: the output force you get when rotating a lever increases the closer said force is to the point of rotation.

The pivot point of the jaw is in the back, which means the molars, which are in the back of the mouth, are closer to the rotation point, and thus can apply more force than the front teeth. This is valuable, because the molars do most of the work of breaking down foods, so they benefit greatly from being able to apply more force.

The trade-off of this is that the further away from the pivot point you go on a lever, the more motion you get. Because of this, the front teeth can separate by a decent bit more than the rear teeth. This also serves the mouth well, because the teeth that most interact with the outside world benefit the most from being able to accommodate differently sized foods. Once a piece is bitten off, it is usually small enough to fit between the molars with some rotation, even if the initial bite required the entire range of motion of the front teeth (e.g. apples).

Another advantage of the layout is that the teeth that are useful for biting off pieces of food line up with the mouth, allowing them to do so, and the molars do not, and the cheeks expand better than the mouth area, allowing food to be moved around to more easily be chewed, without risk of it falling out of the mouth.

I find the layout impressive, but equally as impressive is the fact that humans naturally learn to use the failure modes described above. It takes an understanding of an engineering discipline that is relatively new compared to the length of human existence to describe, in technical terms, what is happening when people eat. But through trial and error, humans learn to do these things without even thinking about it. I find this and the elegant mouth design to be testaments to how effective trial and error can be, given enough time.

Write a comment

Thermal sciences (Wednesday, 16 October 2019 06:33)

Perfect design of the teeth

Thank you for your article

Best wishes